PowerLabs ElectroThermal Gun!

PowerLabs ElectroThermal Gun! |

|

|

|

|

Project Introduction: |

|

|

My particular motivation for starting this research is my ongoing quest for more knowledge in what is currently my favorite research topic; electromagnetic propulsion. As with the railgun research, I am not looking at developing a weapon but rather trying to improve on this technology so that it may become more useful for all of the potential applications it has. |

|

|

|

|

Project Description and Goals: |

|

|

The objective of this research

is to: 1- Produce a compact and reliable .50cal (1/2�, 11.22mm) caliber electro thermal gun also capable of operating in Electro Thermal Chemical regimen. 2- Quantify gun performance in terms of muzzle velocity and kinetic energy for different types of projectiles in both ET and ETC regimen, calculate energy conversion efficiency from electrical power supply, and compare it with a similar conventional propellant gun. 3- Optimize gun design with the ultimate goal of surpassing the conventional propellant gun in muzzle velocity achieved. |

|

|

|

|

Theory (a simplified overview): |

|

Under

Construction The basic design of an ET/ETC Gun consists of

a high voltage pulse discharge power supply, most often a capacitor bank,

that is connected to the gun via a switch capable of handling the very high

currents seen during the discharge. The gun itself is made up o a

barrel with a central electrode surrounded by insulating material at the

breech. Under

Construction The basic design of an ET/ETC Gun consists of

a high voltage pulse discharge power supply, most often a capacitor bank,

that is connected to the gun via a switch capable of handling the very high

currents seen during the discharge. The gun itself is made up o a

barrel with a central electrode surrounded by insulating material at the

breech.A charge, either water, or a water/aluminum slurry, is turned into a plasma via an electrical discharge between the insulator and the barrel material. The plasma generated produces propellant pressure that pushes the projectile out of the barrel. Increasing the breech energy will increase the peak temperature of the plasma and thus the pressures generated. In the case of the ElectroThermal Chemical gun, chemical energy is released when the aluminum powder oxidizes in the presence of water. This energy is in the order of 400J/gram. |

|

|

|

|

Barrel Design: |

|

ET/ETC Gun Barrels serve the exact same purpose as conventional gun barrels;

they hold back pressure generated at the breech, and allow that pressure

to guide a projectile down the length of the barrel. Due to the much higher

temperatures generated at the breech, Electrothermal guns are a lot more

demanding on barrels, and barrels tend to last a lot fewer shots. The main

problem is erosion, followed by the structural limitations of the material,

which can easily be exceeded once the breech energy levels become substantial.

ET/ETC Gun Barrels serve the exact same purpose as conventional gun barrels;

they hold back pressure generated at the breech, and allow that pressure

to guide a projectile down the length of the barrel. Due to the much higher

temperatures generated at the breech, Electrothermal guns are a lot more

demanding on barrels, and barrels tend to last a lot fewer shots. The main

problem is erosion, followed by the structural limitations of the material,

which can easily be exceeded once the breech energy levels become substantial. Specifications: These barrels are made of Heat Trated Cromium Molybdenum steel (4140alloy). They are heat treated for maximum hardness. The barrels have a 1" outer diameter and are bored out to 50 calibre (1/2" inner diameter). The design operating pressure is 60 000PSI.   The barrels are treated with a special bluing solution (a form of oxide

coating to protect the metal) and then varnished on top of the bluing. Corrosion

resistance is important since the ETC gun will be constantly exposed to

electrolytes.

The barrels are treated with a special bluing solution (a form of oxide

coating to protect the metal) and then varnished on top of the bluing. Corrosion

resistance is important since the ETC gun will be constantly exposed to

electrolytes. Here

are the finished barrels (blued and varnished). I used the 1/2 dia. bolt

below as a test for my bluing method. I read on numerous gunsmithing sites

that DIY bluing was not worthwhile; I managed the results pictured here

with a $4.00 bottle of bluing solution and about an hour's worth of cleaning

and polishing. Not bad... Here

are the finished barrels (blued and varnished). I used the 1/2 dia. bolt

below as a test for my bluing method. I read on numerous gunsmithing sites

that DIY bluing was not worthwhile; I managed the results pictured here

with a $4.00 bottle of bluing solution and about an hour's worth of cleaning

and polishing. Not bad... |

|

Setup: |

|

The current setup is embarrassingly primitive, but it works. Since I am not conducting this research at the University or with any external funding, everything is as simple and inexpensive as possible, while still being safe, of course - roulette-game.org. A 12kV 60MA Neon Sign Transformer is rectified by a 100kV X-Ray transformer full wave oil immersed rectifier and then used to charge a 20kV 10uF Aerovox oil filled pulse capacitor. The capacitor is then discharged into the gun through a solenoid actuated ball gap. 12 gauge 40kV high voltage silicone wiring is used for the charging connections and 8 and 4 gauge oxygen free copper cable is used for the gun connections. A high voltage probe is used to monitor charging. |

|

Electrode Design: |

|

Currently

automotive plugs are being employed. This greatly simplifies the design,

even though it is non optimal. Automotive spark plugs are designed to withstand

combustion temperatures of 1600F maximum at pressures of around 1000PSI.

The ETC gun was designed to withstand pressures of up to 60 000PSI and it

is estimated from other works that the plasma temperature is in the 30000

- 50000F range. Currently

automotive plugs are being employed. This greatly simplifies the design,

even though it is non optimal. Automotive spark plugs are designed to withstand

combustion temperatures of 1600F maximum at pressures of around 1000PSI.

The ETC gun was designed to withstand pressures of up to 60 000PSI and it

is estimated from other works that the plasma temperature is in the 30000

- 50000F range.In the future a proper electrode will be designed. Specs on the plugs are: Non resistive, copper cored, 14mm thread.  The center plug has been fired and has had its center section (pillar insulator)

pulverized as a result. I am currently attempting to fill the gap with epoxy

so as to avoid these problems in the future.

The center plug has been fired and has had its center section (pillar insulator)

pulverized as a result. I am currently attempting to fill the gap with epoxy

so as to avoid these problems in the future. |

|

Results: |

|

At

low energies the spark plugs stay together and produce a sharp crack and

a jet of mist that will split thin wooden boards in half. At higher energies

the spark plugs explode in half. At

low energies the spark plugs stay together and produce a sharp crack and

a jet of mist that will split thin wooden boards in half. At higher energies

the spark plugs explode in half.No attempts have been made yet to fire projectiles or to increase energy past 1kilojoule. |

|

Phase 2: |

|

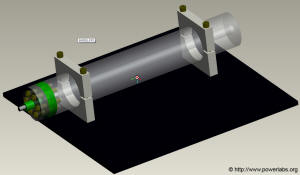

Here

are some renderings of my newest design for an ElectroThermal Gun. Due to

the constant failures, even at low energies, of the spark plugs, I have

decided to design my own breech insulator and center electrode. The center

electrode is now 1/4" thick and made of Molybdenum, and the insulator is

attached in such a way as to require a calculated 138,000PSI to blow apart. Here

are some renderings of my newest design for an ElectroThermal Gun. Due to

the constant failures, even at low energies, of the spark plugs, I have

decided to design my own breech insulator and center electrode. The center

electrode is now 1/4" thick and made of Molybdenum, and the insulator is

attached in such a way as to require a calculated 138,000PSI to blow apart.Energy Source:

Power Switching:

It is triggered by a 5kV pulse from a 1uF capacitor at a current

not to exceed 350A. I will, of course, be grossly over-driving the tube. In literature it has been tested to 100,000Amps for several dozen shots, so I expect it to last the entire initial phase of testing. |

|

|

Comments? Mail me. Last updated 11/02/10 |

|

|

Copyright � 2002 -2003 by Sam Barros.

All rights reserved. Removing any material from this site for display without consent from its author consists in an infringement of international copyright laws and can result in fines up to $50000 per infringement, plus legal costs. |