June 05 2004: Rail Gun Disassembled:

I finally got around to disassembling the gun and examining/photographing

its internals. A lot can be learned from how this design worked, and how

it failed, and this knowledge will be applied on a new, superior design,

which is being designed and built at the moment.

I finally got around to disassembling the gun and examining/photographing

its internals. A lot can be learned from how this design worked, and how

it failed, and this knowledge will be applied on a new, superior design,

which is being designed and built at the moment.

The original PowerLabs Rail Gun was designed in two sections: a

polycarbonate injector with Teflon Rails, and a Rail Gun section with

copper rails and a Garolite G-9 fiberglass composite. The injector was

made from polycarbonate due to its very high tensile strength (10000PSI)

and resistance to shock loads. With the 1/2" thick polycarbonate sheets

holding the Teflon rails under a maximum of 500PSI injection pressure, it

was not believed that this design could fail, thus using polycarbonate

represented a cost saving over the stronger, but much more expensive G-9,

which was used for the rail enclosure where higher forces would be

encountered. In fact, this design was strong enough that it could never

have failed under the calculated load produced by even the highest

possible energies available at the capacitor bank. Failure occurred not

due to Lorenz forces, but rather due to the intense pressure produced when

plasma armatures were repeatedly fired at high energy levels; this higher

pressure was expected, and incorporated into the over design of the gun,

but what was not expected was that the plasma shock actually traveled back

into the injector, and produced enough pressure there to shatter the

material in 5 different places. The breakage of the gun occurred at the

mating point between the polycarbonate and the G-9 materials, indicating

that this connection was clearly the weakest point of the gun. The use of

a weaker material, a two-stage design, and countersunk holes in the

injector bolt holes proved insufficiently strong to withstand repeated

shots at over 10 000Joules. The force of the discharges was enough that,

aside from shattering the Polycarbonate, it bent the steel bolts that held

the injector together, de-laminated the G-9 side supports for the rails,

and deformed the Teflon rail insulators. There is also ample evidence of

plasma blow by past the insulators. This is clearly a source of

inefficiency as the blow by bleeds pressure which would otherwise go

towards accelerating the projectile.

All

of these design weaknesses have been resolved for the Rail Gun 2.0, which

will be a vastly stronger accelerator, capable of firing reliably and

repeatedly at energy levels of at least twice those seen in this first

design. The rail enclosure will now be a single piece made of Garolite

G-11 (a stronger material than G-9) with no counter sunk holes or mating

points. The rail connector exit points in the gun will also be optimized

to minimize stress concentrations. Another advantage of this re-design is

that rail/injector alignment and rail positioning accuracy will be much

greater. It will also be gas tight, which will provide greater

efficiencies when firing plasma armatures. All

of these design weaknesses have been resolved for the Rail Gun 2.0, which

will be a vastly stronger accelerator, capable of firing reliably and

repeatedly at energy levels of at least twice those seen in this first

design. The rail enclosure will now be a single piece made of Garolite

G-11 (a stronger material than G-9) with no counter sunk holes or mating

points. The rail connector exit points in the gun will also be optimized

to minimize stress concentrations. Another advantage of this re-design is

that rail/injector alignment and rail positioning accuracy will be much

greater. It will also be gas tight, which will provide greater

efficiencies when firing plasma armatures.

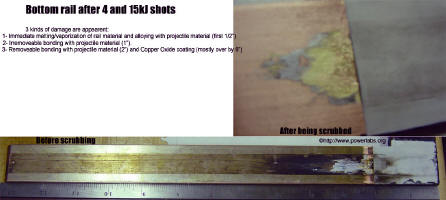

The Rails:

The rails held up surprisingly well; after 12 shots without any

kind of servicing they were completely covered in black carbon soot. This

carbon came from the adhesive in the aluminum tape used in the plasma

armatures burning up. It was useful in evidencing the plasma blow by in

the region of initial rail/armature contact.

After cleaning the rails show evidence of cratering and pitting;

classic effects of electrical arc erosion. Significant amounts of copper

have been removed, and a copper/aluminum alloy formed in the bottom of the

craters. Remote Gambling Association The amount of erosion was lower than expected given the number of

shots fired and their energy level (over 150 000Joules were run through

these rails). The insulators were also virtually undamaged by all the

discharge, evidencing that Teflon is a very suitable insulator for this

particular application.

Interestingly, a second arc crater formed 5.6 inches from the

breech. I believe this was due to the armature not making contact with the

rails until that point during a lower voltage shot. That, together with

the extensive arc damage, evidence to the need for closer machining

tolerances and a tighter rail/armature fit, both planned for the next Rail

Gun.

April 7th: Discovery Channel show aired!

|

Lurking in

the electromagnetic lab at Michigan Technical University is a new kind

of super-hero, an undergraduate obsessed with the power of

electromagnetism: PlasmaBoy.

|

|

March 21: The Rail Gun is on Discovery Channel!

A crew from The Discovery Channel came to my

University to film some of my research on electromagnetic accelerators.

For 10 hours I explained and demonstrated how magnetic fields can be used

to accelerate objects, and how electricity can be stored and converted

into linear motion. The presentations included linear magnetic attraction,

Thompson's coil, the

Coil Gun, and, of course, the Rail Gun.

This should air on "The Daily Planet" some time next month. I'll post the

date as soon as I have the details.

The associate producer for the show insisted that plasma armature shots

were more impressive (I agree). 6 shots were performed with plasma

armatures, at increasingly higher powers. The gun performed flawlessly,

producing some excellent video footage. The last shot, at 14500Joules, was

loud enough to make my ears ring. It also produced enough back pressure to

crack the polycarbonate inductor on 8 different places! The gun will be

repaired soon. As I re-design the barrel to ensure that this can not

re-occur I expect to also make some small upgrades to the gun. The tensile

strength of polycarbonate is 10 000PSI. With only 400PSI on the injector,

my design margin of safety was more than adequate. However it appears as

though the instantaneous localized shock pressures formed when the

aluminum backing on the Teflon projectile turns into a plasma at over 80

000amperes of current must be running in the millions of PSI; sufficient

to blow by the rail insulators and shatter the area around where the

plasma formed. This is very surprising; I expected a lot of pressure, but

not quite this much. It is also very exciting; if the plasma armature is

producing enough force to blow the gun apart, a new design, completely

holding that pressure without deflection should be able to harness it and

convert it into incredible muzzle velocities. Stay tuned, the best is yet

to come!

March

17th: I upgraded the Rail Gun charger with a new transformer and a

half wave voltage doubler. Just like the previous one, this assembly came

from a microwave oven. The voltage doubler allows me to charge up the

capacitor bank to a higher voltage, and to do it faster. This is done in

preparation for the Discovery Channel presentation I will be giving this

Sunday. March

17th: I upgraded the Rail Gun charger with a new transformer and a

half wave voltage doubler. Just like the previous one, this assembly came

from a microwave oven. The voltage doubler allows me to charge up the

capacitor bank to a higher voltage, and to do it faster. This is done in

preparation for the Discovery Channel presentation I will be giving this

Sunday.

My first attempt at fast charging caused the current limiting charge

resistor to go up in smoke (that's a 10 inch ceramic resistor!). I was

forced to bypass it. With the current limiting resistor bypassed the

capacitor bank can be charged to 3000V in under a minute! During

charge/discharge tests the charge resistors overheated and melted their

stand. When the resistors fell on top of the capacitor bank they caused an

explosion powerful enough to shear some bolts and lift the top of the box

up. This was very unpleasant. Nothing was damaged and now that the gun is

clean and tested I feel ready for the presentation tomorrow.

March

16th: I milled a Phenolic block and polycarbonate top to perfectly fit

around the machined rail / inductor connector on the Rail Gun. This block

serves as an insulator for the high voltage connector. With the inductor

now in a permanent mounting position it was time to attempt the first test

firings. These firings are significant in several ways: first of all the

gun now utilizes a much more accurate voltage monitoring system (+- 50V),

which will allow me to make much better calculations relating to

efficiency when I finally get the chronograph to work. Also, the injector

is now operating with Nitrogen. This reduces rail erosion and arcing, and

also, despite the lower pressure (the regulator on the tank will only go

up to 400PSI), should provide a slightly higher muzzle velocity due to

Nitrogen's 30% lower molecular weight. March

16th: I milled a Phenolic block and polycarbonate top to perfectly fit

around the machined rail / inductor connector on the Rail Gun. This block

serves as an insulator for the high voltage connector. With the inductor

now in a permanent mounting position it was time to attempt the first test

firings. These firings are significant in several ways: first of all the

gun now utilizes a much more accurate voltage monitoring system (+- 50V),

which will allow me to make much better calculations relating to

efficiency when I finally get the chronograph to work. Also, the injector

is now operating with Nitrogen. This reduces rail erosion and arcing, and

also, despite the lower pressure (the regulator on the tank will only go

up to 400PSI), should provide a slightly higher muzzle velocity due to

Nitrogen's 30% lower molecular weight.

Finally the addition of the inductor lengthens the duration of the

electrical pulse, lowering current (and thus resistive losses and rail

erosion). Two tests were performed, both with 2300V on the capacitor bank,

amounting to 8300Joules stored energy (less then 50% of what the gun is

capable off; I see no point in burning up the rails with 20KJ before I

actually get the gun working efficiently). The first test utilized an

aluminum foil backed Teflon projectile, and the second one a solid

aluminum projectile. Test videos are available by clicking the respective

test pictures below:

The plasma armature shot was of course much louder. The Teflon

projectile destroyed itself on impact unfortunately (those things are a

pain to machine). Both shots produced significant muzzle flash and

trailing sparks, indicating still significant erosion. The aluminum

projectile had metal smeared on it from beginning to end; a big contrast

from the initial non inductor shots which only eroded the very tip of the

projectile; this means that pulse length is now indeed several times

longer with the inductor. I plan on taking an oscilloscope to the gun and

measuring exactly how much longer the pulse length is. The original (non

inductor) test projectiles are show below next to the inductor-fired

projectile for comparison purposes:

March 8th:

The Rail Gun inductor is now installed! Now all I have to do is mill a

phenolic block to house the custom made copper block connector so as to

insulate it for safety purposes and the gun will be fired in its new

configuration! Stay tuned, big changes are about to happen... Once this

inductor has been used to measure pulse length increase I should be able

to plug the values into my Microsim PSpice circuit simulation and design

an inductor that will bring the pulse length into the 100s of mS, which

will keep the rails under power for several inches of projectile travel

and, if my theory is correct, allow the gun to fire at much higher

efficiencies and velocities. I will also begin some serious work on

getting the Chronograph shielded from the muzzle flash so I can produce

efficiency comparison charts from real muzzle velocity readings. March 8th:

The Rail Gun inductor is now installed! Now all I have to do is mill a

phenolic block to house the custom made copper block connector so as to

insulate it for safety purposes and the gun will be fired in its new

configuration! Stay tuned, big changes are about to happen... Once this

inductor has been used to measure pulse length increase I should be able

to plug the values into my Microsim PSpice circuit simulation and design

an inductor that will bring the pulse length into the 100s of mS, which

will keep the rails under power for several inches of projectile travel

and, if my theory is correct, allow the gun to fire at much higher

efficiencies and velocities. I will also begin some serious work on

getting the Chronograph shielded from the muzzle flash so I can produce

efficiency comparison charts from real muzzle velocity readings.

February

27th: In order to obtain valuable data from Rail Gun test firings, it

is very important to know the amount of voltage in the capacitor bank. The

original Rail Gun design employed a Simpson 10kV probe in the power

supply, which, divided the voltage by 20; as well as being inaccurate, and

requiring a calculator for reading the values, this probe was also behind

the charge current limiting resistor (400Ohms) and so it read a voltage

that was always greater than the real capacitor bank voltage. Finally, if

the bank was shorted out, the probe would read zero, when in fact there

could be some charge in the bank. All these problems have been taken care

off by the addition of an internally assembled Fluke 80K6 6-kV probe. The

probe provides high accuracy real time /1000 voltage readings for my

multimeter and represents exact capacitor bank voltage across the bank's

end terminals, regardless of what resistance is at the rails. Of course,

this means that the voltage dividing resistor has the full 20000J

available to it, and as such everything is located inside the bullet proof

capacitor bank box. February

27th: In order to obtain valuable data from Rail Gun test firings, it

is very important to know the amount of voltage in the capacitor bank. The

original Rail Gun design employed a Simpson 10kV probe in the power

supply, which, divided the voltage by 20; as well as being inaccurate, and

requiring a calculator for reading the values, this probe was also behind

the charge current limiting resistor (400Ohms) and so it read a voltage

that was always greater than the real capacitor bank voltage. Finally, if

the bank was shorted out, the probe would read zero, when in fact there

could be some charge in the bank. All these problems have been taken care

off by the addition of an internally assembled Fluke 80K6 6-kV probe. The

probe provides high accuracy real time /1000 voltage readings for my

multimeter and represents exact capacitor bank voltage across the bank's

end terminals, regardless of what resistance is at the rails. Of course,

this means that the voltage dividing resistor has the full 20000J

available to it, and as such everything is located inside the bullet proof

capacitor bank box.

February

20th: I finally got a Nitrogen tank for my lab. The tank is charged to

3000PSI and has a 0-400PSI gas regulator on it. Using Nitrogen Gas for the

Rail Gun projectile injector will increase muzzle velocity (due to the

fact that N2 has a lower molecular weight) and also protect the rails from

oxidation by purging oxygen. February

20th: I finally got a Nitrogen tank for my lab. The tank is charged to

3000PSI and has a 0-400PSI gas regulator on it. Using Nitrogen Gas for the

Rail Gun projectile injector will increase muzzle velocity (due to the

fact that N2 has a lower molecular weight) and also protect the rails from

oxidation by purging oxygen.

I finished machining the copper connectors for the Rail Gun inductor. The

connectors are solid copper, one bolts on to the capacitor bank inside the

case directly to the end bus bar (thus avoiding exposed HV-carrying parts)

and the second one to the rails through a machined solid copper billet.

New Sponsor!: Below is a photograph of 12 neodymium N45 grade supermagnets each 2x2" base

with a 2x1" top and one inch high. These are the strongest magnets I have

ever seen; in one word, they are Dangerous. Strong enough to crush

fingers, drive metal objects through soft wood, or explode on impact when two

are released together. I will be employing their fantastic field strength as

external field augmentation for higher efficiencies in Rail Gun 2.0. They

have been sponsored by Engineered

Concepts; the cheapest and best magnet supplier on the 'net!

February 18th xmicrogamingcasinos.com: The players familiar with online gambling world know that Microgaming creates one the most reliable and popular software out there. A film crew from Discovery Channel is coming here

this Saturday to film the Rail Gun for The Daily Planet and I decided to

upgrade the gun with pulse shaping inductors for the show. I'm somewhat

worried that I'm gambling with too many unknowns so close to a major

presentation but at the same time I am now thoroughly convinced that the

gun does need extra inductance; the pulse length is simply too fast at

63uS; my projectile scorch marks on the rails are under one inch in length

and I can't see any real high efficiency acceleration coming from that

short a travel under power; the smallest research RailGun I've seen to

date was one meter long (granted, it also fired at 200kJ stored) and I'm

assuming it used all 100cm of it to accelerate the projectile to 2km/s.

I'll lose a lot of magnetic force by lowering the current but right now

given current results I am convinced it is worth it. The inductor mounts

are almost complete.

Without an LCR meter, an inductor meter or an oscilloscope I have no idea

what the inductance I am adding to the gun is, but I suspect it is not

nearly enough. Nonetheless, it should start improving results; at 20kJ,

even an improvement of 0.1% in efficiency can make the projectile move

several hundred feet per second faster... That's what I love about working

with big energies :) Can't wait to finish this project and get the 46kJ

capacitor bank out... Can you say "hypervelocity"?!

February 11th: More plasma shots, and new discoveries!

I fired off two more plasma armature shots yesterday; possibly my last

two before the rail gun disassembly for the pulse lengthening inductor and

improvements to the capacitor charge voltage monitoring system.

These shots aimed at testing 3 new ideas/developments and brought about

some new and unexpected discoveries. Below you can see the set up used for

these two shots:

The Rail Gun was set up in the back of the laboratory firing across it

into a trash can full of various materials, from foam to rubber, cloth and

wood. Charging and firing was done remotely from a test stand.

The first test involved a specially shaped projectile: the

triangular tip aims to improve aerodynamics and allow the projectile to

move faster. The back is shaped inwards, with the intent of causing the

propellant pressure to open it up and thus seal it better against the

sides of the barrel. I believe a better seal may prove beneficial in

obtaining higher velocities from the plasma armature, and I know from

observing the first plasma propelled projectile that the plasma armature

is overtaking the projectile (blowby) and causing efficiency losses as it

continues to accelerate on its own.

On this shot's after shot picture (next to projectile picture) it can be

seen that the projectile hit the foam perfectly on its side and cut a neat

impression of it through the foam. The blackening of the sides is from

rubbing against the sides of the rails; the lack of burn marks indicates

that blowby has been reduced. Plasma is still leaking past the top and

bottom of the projectile. This can be reduced by machining a closer

fitting projectile but at some point friction may become too great to and

negate any increase in efficiency from the reduction of blowby. This shot

was not as loud as the first one, and it produced more sparks, indicating

that the aluminum was not completely turned into a plasma. It was however

very fast, penetrating deep into the backstop.

The second test was an attempt at increasing projectile mass; a

sharpened tungsten spear was placed inside a tapered Teflon projectile.

Two layers of aluminum foil were crumpled behind it in order to study the

effect of having a greater mass of aluminum to produce a denser plasma

armature. This shot yielded very surprising results:

The massive muzzle flash and shower of sparks indicates that a lot of

energy was spended in melting and vaporizing the aluminum, and some of it

did not completely turn into a plasma. The shot was *very* loud; the

loudest I have ever heard from this gun. It was also very fast,

penetrating deep into the projectile stop and only stopping when it cut

into one inch of vibration dampening rubber mat. The tungsten spear was

blown out of the hole and into the target, whereupon it disappeared.

Despite the blowby evidenced by scorch marks on the sides of the

projectile, and the pressure leakage from the hole formed when the spear

exited still inside the barrel, this was the fastest shot to date, very

likely to have been supersonic. I believe this was due to the larger mass

of aluminum behind the projectile producing a greater plasma density and

propellant pressure from the vaporization and superheating of the

aluminum. This is counter intuitive as I would expect the energy lost in

vaporizing the aluminum to decrease acceleration efficiency, but

apparently there is a mass of aluminum vs efficiency curve that peaks

somewhere above a single strip behind the projectile. This is very

interesting! I also suspect the ideal mass of aluminum used for a plasma

armature may increase with increased stored energies.

I look forward to firing the gun with pulse shaping inductors very soon,

and attaining unprecedented efficiencies and very high velocities. I

believe the gun has surpassed mach 1, and mach 2 may be within reach at a

full 20 000Joules stored energy.

On the meantime I apologize for the lack of chronograph readings (which,

of course, are the only truly meaningful of accessing real efficiencies)

and invite you to enjoy the following video, showing the test firing of a

conventional (metal) armature projectile and all my 3 plasma armature

shots to date, for comparison purposes. The last shot is the one using the

extra aluminum foil backing, notice how much louder it

sounds. Click on slideshow for video.

February 6th: Rail Gun Plasma shot!

Click on the picture to download video. The video is approximately

50 seconds long, 10MB. It shows me bypassing the safety fuse on my power

supply, charging the Rail Gun air tank to 450PSI, and loading an aluminum

backed Teflon slug into the barrel. The first shot is aimed at an apple.

It fails in that the aluminum backing does not form an electrical

connection with the barrel and thus the projectile "only" reaches +-

600fps from air alone before blasting the apple to pieces against the

backstop. The second shot is performed at a much lower 100PSI and with a

starting velocity of around 70m/s the projectile is now further

accelerated by a plasma armature, leaving the barrel with the sound of a

rifle shot and proceeding to perforate the backstop and embed itself into

a catalogue. The muzzle blast is a lot cleaner, with no sparks and nothing

but a concentrated 5 - 6 feet long purple plasma "flame" leaving the

barrel. The gun is also (not too surprisingly considering the extremely

high temperatures and resulting pressures of a multi megawatt plasma)

much louder with the plasma armature. Still no chrono readings but I

am now thoroughly convinced that a pulse shaping inductor is in order.

Details for the shot: 100PSI, 2.2KV.

More video to follow. Comments are always welcome.

This is the projectile after being fired with an aluminum

armature. Notice the massive amounts of plasma blow by which scorched it

and left it with black marks on all sides. This plasma blow by is an

efficiency loss that must be corrected.

January 30th: Pictures of my new laboratory:

I think I've figured out how to mount the inductor. I will use an

internal connection and a lathe made (by myself of course) massive copper

plug/jack assembly. Machining begins tomorrow.

January

22nd: I am back from my co-op as a Systems Engineer at Vermont Yankee

Nuclear Power station, and there have been many changes to the Rail Gun

project. First of all the Advanced Space Propulsion laboratory where I was

currently working received a new vacuum chamber, which now takes up all

the available space. My research has thus been moved to the Sub Basement

of the Mechanical Engineering building at Michigan Technological

University, at the Internal Combustion Engine and Dynamics Research

Laboratory. It is a much larger lab, where I have my own desk, table and

storage space. On January 20th the gun was moved to its new location and

set up, and on January 21st it was fired for filmed presentation for TV6,

a local news station. It performed well. I'll upload the video when I get

it. Gambling Commission January

22nd: I am back from my co-op as a Systems Engineer at Vermont Yankee

Nuclear Power station, and there have been many changes to the Rail Gun

project. First of all the Advanced Space Propulsion laboratory where I was

currently working received a new vacuum chamber, which now takes up all

the available space. My research has thus been moved to the Sub Basement

of the Mechanical Engineering building at Michigan Technological

University, at the Internal Combustion Engine and Dynamics Research

Laboratory. It is a much larger lab, where I have my own desk, table and

storage space. On January 20th the gun was moved to its new location and

set up, and on January 21st it was fired for filmed presentation for TV6,

a local news station. It performed well. I'll upload the video when I get

it. Gambling Commission

Work must now progress quicker, as the gun will soon be featured on

Discovery Channel.

Work must now progress quicker, as the gun will soon be featured on

Discovery Channel.

As such I have decided to tackle the first problem and largest

inefficiency cause in the gun: the pulse length is extremely short (63uS)

and causes all of the energy to be dissipated in a very small segment of

the rails: some times as little as 1 inch! With such a fast, there are two

problems: Power amounts to the energy in the capacitor divided by the

discharge time. With the current pulse length of 63uS a full 20kJ charge

will dump nearly 330MW, or 90 thousand amperes on the rails. Resistive

losses are a product of the square of the current, so even the relatively

small rail and (particularly) arc contact resistance of the gun there is a

LOT of energy being lost. This loss manifests itself as low efficiency and

a dramatic erosion to the rails. Also, with such a short pulse, the

magnetic field formed behind the projectile is non optimal. By lengthening

the pulse, acceleration will occur for a longer period of time, rail

damage will be spread out over a larger area, and resistive losses will

decrease. The accelerating force may be lower, but I theorize that this is

the way to go for higher efficiencies.

So how to increase the pulse length?

With an inductor of course. This picture shows my first

two prototypes: A toroidal air-cored (non-saturable) inductor with 23 turns of

insulated AWG 4 oxygen free copper wire around a 2.35 diameter PVC pipe

loop. The loop outer diameter is 8" on average. Anyone who has taken apart

a power supply will recognize this as a super size version of a very

common component in DC power supplies :) The second one utilizes the exat

same amount of wire and turns but is a linear arrangement. The inductor will be added in

series with the rails and slow down the pulse. A detailed analysis of this

will come soon. A second inductor is also being built so series vs.

parallel arrangements can be tried. I suspect eventually the gun will be

using a lot more inductance than this. But its a start... Figuring out how

to connect it to the gun will be a challenge of its own... With an inductor of course. This picture shows my first

two prototypes: A toroidal air-cored (non-saturable) inductor with 23 turns of

insulated AWG 4 oxygen free copper wire around a 2.35 diameter PVC pipe

loop. The loop outer diameter is 8" on average. Anyone who has taken apart

a power supply will recognize this as a super size version of a very

common component in DC power supplies :) The second one utilizes the exat

same amount of wire and turns but is a linear arrangement. The inductor will be added in

series with the rails and slow down the pulse. A detailed analysis of this

will come soon. A second inductor is also being built so series vs.

parallel arrangements can be tried. I suspect eventually the gun will be

using a lot more inductance than this. But its a start... Figuring out how

to connect it to the gun will be a challenge of its own...

June 17th: Today was my safety review day; had my

advisor and a pulsed power professor from the EE department look over all

my schematics and gun wiring and make some suggestions before I begin

firing the gun in the University. The required modifications are as

follows:

1- Replace steel Rail Gun mounting bolts for Nylon ones.

2- Place safety cover on discharge switch.

3- Ground Rail Gun barrel bolts or replace them for fiberglass reinforced

nylon ones.

4- Make projectile backstop (must be able to stop a rifle round).

Looks like I'll be busy... The gun might also be moved to another

laboratory on the 5th floor of the Mechanical Engineering building... No

more powered testing for another couple of weeks. On my side, my current

plans for the gun are to build a muzzle flash suppressor so I can use it

with a light break chronograph, to test fire it with a plasma armature and

to obtain oscilloscope traces of the gun firing with metal and plasma

armatures. With the data from those shots I will begin work on an inductor

and then possibly a power switch.

June 16th: After a series of tests with the rail gun

injector I obtained a more accurate plot of the velocity imparted to the

projectile at 6 feet from the muzzle versus the pressure present on the

injector air tanks at the time of firing. It is very interesting to note

that the curve follows what appears to be a logarithmic plot; I.E.

doubling the pressure in the air tank will quadruple the amount of energy

stored in it and make a lot more noise during firing but will not at the

same time double the injection velocity; it appears as though after a

certain point increasing the pressure substantially will not result in

very substantial velocity increase. Currently the injector is firing at

150m/s, with a variation of +- 2m/s between shots. This injector is also

able to fire a Teflon projectile at 195m/s (634.5fps, 696km/h, 432.6mph). It is important to note that

when power is applied to the projectile it is only halfway through the

rails and therefore not traveling as fast as the ultimate injection

velocity, but these will be the values used for calculating the gun

efficiency. I plan on making a chart of injector pressure vs. kinetic

energy to see if that is more linear. Current kinetic energy for the gun

is 67.5Joules prior to injection. This is quite insignificant when

compared to the 20 000 that is being applied electrically to the

projectile during firing.

June 13th: Thyrathon switched Rail Gun? Maybe not: this is

what

L-3 electron devices had to say about my idea:

"Sam,

Our thyratron engineer looked at your requirements and suggested a spark

gap. It was beyond the capability of the thyratrons that we currently

manufacture.

Buzz Miklos"

A spark gap, huh? Considering how loud the one on my Tesla

Coil was while switching .5joules, I think I will pass on a 360 megawatt

spark. Looks like I will just have to build my own thyrathon... I

practiced some oxyacetylene metal cutting today. Next week I will work

some more on the muzzle flash suppressor and on some gun documentation for

the safety review on Tuesday.

June

12th: Finished wiring the power supply, installed the air tank,

hydrostatically tested it to 600PSI. It appears as though the extra

pressure is not all that beneficial to muzzle velocity: the gun right now

is clocking around 500fps with 500PSI in the tank. June

12th: Finished wiring the power supply, installed the air tank,

hydrostatically tested it to 600PSI. It appears as though the extra

pressure is not all that beneficial to muzzle velocity: the gun right now

is clocking around 500fps with 500PSI in the tank.

Today was the big day! After testing all systems the Rail Gun capacitor

bank was charged to 1700V, which yields an energy stored of just under 9kJ

and the gun was fired into a very heavy catalogue. I suspected that the

muzzle flash would "blind" the very sensitive light break chronograph and

attempted using three sheets of corrugated cardboard as a makeshift muzzle

flash suppressor. It did not work well enough that the chronograph gave me

a reading (it just said "error", as it does when a picture is taken inside

the room) but the shot was nonetheless spectacular. It was about as loud

as firing a gun inside the room (from now on earmuffs a must!), the air

filled with an acrid ozone smell, computer monitors flickered and the

projectile had enough energy to punch into 700 pages of the 1500+ page

catalogue. With air alone at 500PSI the projectile barely sticks to the

paper. It is not possible yet to determine if the projectile is going

supersonic or not but the gun is definitely imparting a substantial amount

of kinetic energy to the projectile!

Below are some pictures of the setup and the damage caused by the shot.

The video is available for download at the bottom.

A quick note about Rail Guns: The muzzle flash that occurs when the

gun is fired is unavoidable and a direct byproduct of their operating

method (sliding electrical contact). The flash and sparks are seen every

time the gun is fired and although they represent a power loss, they are

an unavoidable one. I find it somewhat sad that certain jealous

individuals need to repeat over and over again on a message board that my

rail gun shoots sparks as though that was some kind of defect.

And at last, what you were all looking for:

The Rail Gun >9KJ Test Fire Video!;

air at 500PSI and >9000J on the capacitor bank. BTW for comparison purposes

the injector is imparting approximately 80J of kinetic energy into the

projectile right now. I will need a better camera than my Sony digital

camera to capture more frames of the muzzle flash but this gives a good

idea of what the firing looked like live. Look forward to more powered

testing as soon as I build a more effective way to shield the chronograph!

June

11th: Finished wiring and building the temporary high voltage

power supply. It is pretty crude, made from wood an without too much

engineering behind it but as the name implies it, all I want it for are

some preliminary tests. I got around the safety concern of using wood by

having all the connections inside the power supply being made from high

voltage rated wire. The PSU is grounded and a 1:20 high voltage probe is

being used to monitor charge voltage. I charged up the Rail Gun today to

2000Volts (about 7KJ) and discharged it through its discharge resistors.

Everything is working well but I might in the future reduce the size of

the discharge resistors and the charge resistor so as to make everything

charge/discharge faster. June

11th: Finished wiring and building the temporary high voltage

power supply. It is pretty crude, made from wood an without too much

engineering behind it but as the name implies it, all I want it for are

some preliminary tests. I got around the safety concern of using wood by

having all the connections inside the power supply being made from high

voltage rated wire. The PSU is grounded and a 1:20 high voltage probe is

being used to monitor charge voltage. I charged up the Rail Gun today to

2000Volts (about 7KJ) and discharged it through its discharge resistors.

Everything is working well but I might in the future reduce the size of

the discharge resistors and the charge resistor so as to make everything

charge/discharge faster.

I also got around to painting the new injector and the temporary

power supply box. Glossy black enamel of course; my favorite color for

weaponry :)

June 10th: Threaded the 1/2" brass valve connection in

place, glued it with 6 hour metal epoxy and filled the CNC machined 1/2"

polycarbonate valve connection piece with two part epoxy for added

strength, finished gluing everything. Tomorrow the tank will be painted

and the old one will be removed. Hydrostatic testing will hopefully take

place on Thursday, with test firing possibly occurring the same day. June 10th: Threaded the 1/2" brass valve connection in

place, glued it with 6 hour metal epoxy and filled the CNC machined 1/2"

polycarbonate valve connection piece with two part epoxy for added

strength, finished gluing everything. Tomorrow the tank will be painted

and the old one will be removed. Hydrostatic testing will hopefully take

place on Thursday, with test firing possibly occurring the same day.

While I waited for the glue to dry I worked some more on the

Power Labs High Efficiency Coil Gun prototype.

June 9th: Glued the PVC elbows, end caps, pipe and tee

together and screwed the brass elbows and brass tee together with teflon

tape. I drilled and tapped a hole on one of the end caps for the brass

filling system to go into and filled the cap up to 1/4 inch depth (6mm)

with metal epoxy so as to strengthen the plastic pipe that had been

weakened by the threading. I also CNC milled a precision flat end cap for

the middle of the tee where I will thread the valve attachment. Tomorrow

hopefully I will paint the completed air tank and it will be ready for

hydrostatic testing on Wednesday. I will probably hydrostatically test it

all the way to 650 or even 700PSI due to the extremely dangerous nature of

the high pressures that this tank will hold.

June 7th: The parts for the new 500PSI Rail Gun injector

arrived today. The new ball valve and pressure gage attachment will allow

me to charge the gun up with air at a very accurate pressure and close off

the tank, which would make it possible to take the charged injector to a

remote place where testing could be performed without a source of air. The

1 1/4 SCH 80 PVC looks very strong, and I would most definitely feel safer

around it at 500PSI than I did around the 1 1/2 SCH 40PVC at 300.

Lets just hope the 300 PSI solenoid valve feels the same way I do.

June

05: I spent most of my day practicing some MIG welding for the

Junkyard Wars show I'm going to be in on 37 days, but I still found some

time to test the temporary Rail Gun charger and build more of the box that

will house it. I also got a high voltage test probe from one of the

electricians here, so as far as parts go I'm all set! I charged the gun up

to 200V today and everything works beautifully. June

05: I spent most of my day practicing some MIG welding for the

Junkyard Wars show I'm going to be in on 37 days, but I still found some

time to test the temporary Rail Gun charger and build more of the box that

will house it. I also got a high voltage test probe from one of the

electricians here, so as far as parts go I'm all set! I charged the gun up

to 200V today and everything works beautifully.

June 04: Non metals centre still closed (they are

re-varnishing the tables there and so no dust can go into the room). I cut

a polycarbonate square for the rectifier bridge, helped a friend clean his

motorcycle engine and built an entire coil gun so as to have something to

do for the afternoon. The new coil gun will have its own dedicated page

some time soon; stay tuned.

I made a chart relating the rail gun injector muzzle velocity with the air

pressure present on the air tank at the moment it was fired. This data is

preliminary as the pressure measurements were read off the regulator and

since it has a 4000PSI scale it is difficult to read accurately at such

low values. We can see that the relationship is somewhat linear, but that

after 200PSI further increases in pressure do not seem to be causing equal

increases in velocity (or perhaps the projectile became damaged after the

3rd test).

A more accurate chart will be created once the new injector is ready.

June 03: The non metals centre was closed so I could not

work on the charging power supply box. I gave the projectile injection

issue some more thought and decided that the current injection velocity

would require a very significant amount of inductance to be placed on the

circuit, which will produce a lot of undesirable oscillations and thus

make it very difficult for a solid state switch to be implemented into the

circuit in the near future. In order to lower the induction requirement I

quickly designed a new, intermediate pressure injector by designing an air

tank made from 1 1/4 inch SCH 80 PVC as opposed to the current 1 1/2 SCH

40 PVC. This changes the working pressure of the air tank from 330PSI to

520PSI, although it will involve over loading the solenoid valve a certain

amount. The gun injector should be operating at 500PSI

and having accurate pressure monitoring built into it starting next week.

Below is a list of the materials that will be used for the conversion.

Doubling the air pressure inside a tank quadruples the energy stored,

therefore the new injector should be firing with perhaps 60% higher

velocity, maybe more when Nitrogen is used. I am still working on the

final design, for the second Rail Gun to be built which will employ

3000PSI valves and should achieve supersonic velocities.

|

Quantity |

Description |

Unit

Price |

Ext.

Price |

Ships |

|

1 EA

|

Dual Scale

Steel-Case Gauge 2% Mid-Accuracy 2" Dial, 1/4" NPT Bottom, 0-600 Psi |

$7.24

EA |

$7.24 |

today |

|

2 EA

|

Brass Threaded

Precision Pipe Fitting 1/4" Pipe Size, 90 Degree Male Elbow, 4100 Psi |

$7.09

EA |

$14.18 |

today |

|

1 EA

|

Brass Threaded

Precision Pipe Fitting 1/4" Pipe Size, Tee, 3000 Psi |

$6.41

EA |

$6.41 |

today |

|

1 EA

|

Extruded Brass

Threaded Pipe Fitting 1/2" Pipe Size, Fully Threaded Nipple, 1-1/8"

Length |

$1.52

EA |

$1.52 |

today |

|

1 EA

|

Dark Gray PVC

Schedule 80 Unthreaded Pipe 1-1/4" Pipe Size X 5' Length |

$4.49

EA |

$4.49 |

today |

|

2 EA

|

PVC Sch 80

Unthreaded Pipe Fitting-Dark Gray 1-1/4" Pipe, 90 Deg Elbow |

$2.60

EA |

$5.20 |

today |

|

1 EA

|

PVC Sch 80

Unthreaded Pipe Fitting-Dark Gray 1-1/4" X 1" X 1-1/4" Pipe, Reducing

Tee |

$5.16

EA |

$5.16 |

today |

|

2 EA

|

PVC Sch 80

Unthreaded Pipe Fitting-Dark Gray 1-1/4" Pipe, Round Cap |

$3.78

EA |

$7.56 |

today |

|

1 EA

|

Plastic-Pipe

Cement PVC Heavy Duty, 8 Ounce Dauber-Top Can, Clear |

$2.93

EA |

$2.93 |

today |

|

1 EA

|

Chrome-Plated

Brass Ball Valve W/Lever Handle 1/4" NPT Female Connections |

$4.03

EA |

$4.03 |

today |

|

1 EA

|

Extruded Brass

Hex Nipple 1/2" Pipe Size, 1-13/16" Length |

$2.03

EA |

$2.03 |

today |

|

1 EA

|

Extruded Brass

Threaded Pipe Fitting 1/2" Pipe Size, Fully Threaded Nipple, 1-1/8"

Length |

$1.52

EA |

$1.52 |

today |

|

1 EA

|

Extruded Brass

Threaded Pipe Fitting 1/4" Pipe Size, Fully Threaded Nipple, 7/8"

Length |

$0.49

EA |

$0.49 |

today |

|

Total: |

$62.76 |

June

02: 7 hours of work today. The day started off bad when, after

building a full wave bridge rectifier for the high voltage charging supply

my volt meter caught fire during a low voltage measurement (cheap radio

shack piece of ...). I did get a current measurement though, but it was

off scale for the meter (>500mA). After dinner my allied electronic order

for HV connectors had arrived, as had my shooting chronograph, and so I

decided to go back to the Advanced Space Propulsion lab and do some more

work. I removed the old coaxial power connectors from the capacitor bank,

re-drilled the connector feed through hole, along with 8 more bolt holes

for securing the new connectors, bolted down the two new MHV 5kV

connectors in place and wired everything back up, including the last 8

bleeder resistors and the capacitor bank end terminals. I ended up

crimping the bleeders on to the end terminals so next time the gun is open

I will do a more professional job and drill holes at the capacitor bank

end bars so they can be bolted on, but for now THE GUN IS COMPLETE AND

READY TO FIRE! As soon as the capacitor bank charging supply is built

testing will resume. June

02: 7 hours of work today. The day started off bad when, after

building a full wave bridge rectifier for the high voltage charging supply

my volt meter caught fire during a low voltage measurement (cheap radio

shack piece of ...). I did get a current measurement though, but it was

off scale for the meter (>500mA). After dinner my allied electronic order

for HV connectors had arrived, as had my shooting chronograph, and so I

decided to go back to the Advanced Space Propulsion lab and do some more

work. I removed the old coaxial power connectors from the capacitor bank,

re-drilled the connector feed through hole, along with 8 more bolt holes

for securing the new connectors, bolted down the two new MHV 5kV

connectors in place and wired everything back up, including the last 8

bleeder resistors and the capacitor bank end terminals. I ended up

crimping the bleeders on to the end terminals so next time the gun is open

I will do a more professional job and drill holes at the capacitor bank

end bars so they can be bolted on, but for now THE GUN IS COMPLETE AND

READY TO FIRE! As soon as the capacitor bank charging supply is built

testing will resume.

With the gun ready and more powered tests imminent, it was

time to start getting some muzzle velocity measurements. I set up a gun

chronograph 6 feet away from the gun barrel with multiple cardboard sheets

and wood as a backstop and fired several rounds through the chronograph.

At 300PSI, the gun consistently fires a 1x1x.25" (25x25x6mm) 6 gram

aluminum slug at over 450feet per second (137m/s), with a top muzzle

velocity of 482.5fps (147m/s, 529km/h, 329mph). This amounts to 64J

kinetic energy, although on these tests the entire 2 feet length of the

injector + rails is providing acceleration: on a powered test after 13

inches the electricity starts to provide more acceleration, and so the

actual projectile injection velocity is a value significantly lower than

the ones quoted here. The primary function of the injector is to simply get the

projectile moving so that it does not weld in place inside the rail gun

barrel, and as such any moderate velocity should suffice. However, even at

147m/s with the measured 63.4uS pulse length the projectile will move only

9mm under power if we assume no electrical acceleration. I find it

unlikely that this gun is going to work with a metal armature until I

design and implement a pulse lengthening inductor into the circuit, but

before this happens I first plan on obtaining data for muzzle velocities

with metal armatures and, more importantly, plasma armatures.

Click on the shooting setup picture below to view a Rail Gun muzzle

velocity measurement video (the video is somewhat dark because the

chronograph can not be used under fluorescent lighting).

I am also currently designing a new injector for the gun.

Given the one foot (30cm) barrel length limitation on this gun it seems

likely that the new injector will run at very high pressures, possibly

1000PSI - 3000PSI. Ideally, the goal would be to inject the projectile at

supersonic velocities and increase its velocity further by another mach

number or two.

May 30th: Ordered new high voltage connectors (MHV

Military grade 5kV connectors, $22.50 a pair) for the capacitor bank and a

Chrony F1 gun chronograph, 30 - 7000fps range 99.5% accuracy, so that I

can start gathering some hard data on muzzle velocities and efficiencies.

Today I officially begun work on the power supply, buying a panel ammeter

and an analogue voltmeter. I put the variac and transformer together and

obtained some voltage measurements from the combo. The transformer is a

1:20 current limited (shunted) step up transformer and put out 1000V at

50V input from the variac. Monday I hope to assemble a full wave bridge

rectifier for it and start work on a power supply box. I still need a

voltage divider so that I can measure the actual capacitor bank voltage as

it charges up, all the way to 3600 Volts, but my advisor may be able to

help me with that.

February 5th: 4 hours of work: Fine tuned the rail

spacing on the gun, milled some Teflon ammunition for it and did some

tests with the new ammo. Teflon shoots FAST! Low weight and a low

coefficient of friction should allow it to be injected at near supersonic

velocities.

February 3rd: 3hours of work:

Polished the rails ,

first with 400grit sandpaper, then with Brasso, a mildly abrasive ammonia

based metal cleaning product. Looks pretty good; I could have made it

better but I don't think it will matter too much after the first couple of

shots turn the mirror like finish of the rails into a mixture of metal

oxides, blasted holes and molten metal droplets... The gun is now once

again re-assembled, but I still need to adjust the exact spacing on the

rail insulators since the rails are now exactly 1/100th of an inch

thinner. ,

first with 400grit sandpaper, then with Brasso, a mildly abrasive ammonia

based metal cleaning product. Looks pretty good; I could have made it

better but I don't think it will matter too much after the first couple of

shots turn the mirror like finish of the rails into a mixture of metal

oxides, blasted holes and molten metal droplets... The gun is now once

again re-assembled, but I still need to adjust the exact spacing on the

rail insulators since the rails are now exactly 1/100th of an inch

thinner.

I also finally got around to installing the bleeder / charge equalizing

resistors; Each one of the 40 resistors had to have its terminals

individually bent and than have a terminal crimped in place on it (80

terminals). Than I had to disassemble the capacitor bank, unbolt all the

capacitor terminals (64 in total) and re-bolt them with the resistors in

place. I got 4 blisters on my hand from doing that. Still have 8 bleeder

resistors to go: these will go across the last row of capacitors when I

install the end terminals. Right now the capacitor bank will have to

remain open though because my advisor will not allow me to use coax

connectors on the bank and therefore I have to find a supplier for High

Voltage connectors and have those fitted on the capacitor bank. Finding

High Voltage (4kV 1A) connectors is proving to be far more of a challenge

than I originally expected.

I also finally got around to installing the bleeder / charge equalizing

resistors; Each one of the 40 resistors had to have its terminals

individually bent and than have a terminal crimped in place on it (80

terminals). Than I had to disassemble the capacitor bank, unbolt all the

capacitor terminals (64 in total) and re-bolt them with the resistors in

place. I got 4 blisters on my hand from doing that. Still have 8 bleeder

resistors to go: these will go across the last row of capacitors when I

install the end terminals. Right now the capacitor bank will have to

remain open though because my advisor will not allow me to use coax

connectors on the bank and therefore I have to find a supplier for High

Voltage connectors and have those fitted on the capacitor bank. Finding

High Voltage (4kV 1A) connectors is proving to be far more of a challenge

than I originally expected.

Until I get the high voltage connectors I plan on working on the

capacitor bank charging supply.

January 26th:

4 hours of machine shop work today; I replaced all the SS bolts on the

capacitor bank top for Nylon bolts and milled off 1/100th of an inch from

the rail surfaces so as to remove the damage caused by the previous 2

shots. I still need to install the charge equalizing/bleeder resistors and

replace the charging high voltage connectors (as per my advisor's

recommendations) and the gun will then finally be ready for testing in the

University labs!

12/21/02:

I finally obtained a high voltage charging supply for the Rail Gun

Capacitor bank: The charger consists in a Samsung Inverter Tecnology

Microwave Oven Power Supply: 1.5kW continuous, 4kV adjustable. I also

bought 20 1inch^2 1/2inch thick grade N38 Neodymium Supermagnets. These

are STRONG! The kind of magnets that will explode into pices with the

impact of letting two come together. They will be employed on my second

Rail Gun prototype as soon as testing is complete with the first

prototype. 12/21/02:

I finally obtained a high voltage charging supply for the Rail Gun

Capacitor bank: The charger consists in a Samsung Inverter Tecnology

Microwave Oven Power Supply: 1.5kW continuous, 4kV adjustable. I also

bought 20 1inch^2 1/2inch thick grade N38 Neodymium Supermagnets. These

are STRONG! The kind of magnets that will explode into pices with the

impact of letting two come together. They will be employed on my second

Rail Gun prototype as soon as testing is complete with the first

prototype.

11/17/02: The bleeder

/ charge equalizing resistors have arrived ($140, from allied

electronics). They are rated at 10W, 50kOhms, 5% tolerance, wire wound.

Now I have to sort out the 32 best ones from the pack of 50 (best meaning

closest to the value of 50k), solder end terminals to all of them, connect

one across each individual capacitor in the bank, re-drill and re-tap the

holes on the capacitor bank top for Nylon bolts, and re-assemble the gun.

Work resumes Monday.

11/01/02: In order to

fire the gun in the University some safety features are required by the

building safety committee; namely high voltage rated connectors and

bleeders. At the moment I am still waiting for the bleeder resistors so I

can resume testing at the University. I will also be presenting it for

some University Physics classes. Since I don't have any machine shop work

to do until the resistors arrive I have been working on some mathematical

models for the gun. On the Rail Gun page you

will find the PSpice schematic I am using to simulate the gun. It

incorporates measured values for capacitor ESL and Capacitance as well as

calculated values for Rail and circuit resistance. I hope to have some

simulation snapshots up soon.

Also, due to the overwhelming demand for it I decided to make the

Rail Gun 15kJ Test Shot Video available.

I was hoping someone would e-mail me one of the better videos taken at the

presentation since the only video I had (where the snapshots came from)

was captured from an analogue camera using my notebook TV Tuner Card,

meaning that it is both low quality and doesn't have any sound. I put the

sound of the 300 PSI shot over the video so its not all silent. Until I

get some better video I guess this is all I'll have available.

10/21/02:

Got around to opening up the gun today...Very interesting! As expected the

rails erosion took place on a similar length to that at which the

projectile was damaged. This further confirms my hypothesis that the pulse

was short enough that the projectile didn't even get to be fully injected

into the rails before all the energy was gone. I was however very

satisfied at how well the spacers and the rail insulators took the

discharge: There was absolutely NO damage to either and the residue that

accumulated was not excessive and very easily removed. Looks like the gun

should be able to fire several times before I have to take it apart for

cleaning. 10/21/02:

Got around to opening up the gun today...Very interesting! As expected the

rails erosion took place on a similar length to that at which the

projectile was damaged. This further confirms my hypothesis that the pulse

was short enough that the projectile didn't even get to be fully injected

into the rails before all the energy was gone. I was however very

satisfied at how well the spacers and the rail insulators took the

discharge: There was absolutely NO damage to either and the residue that

accumulated was not excessive and very easily removed. Looks like the gun

should be able to fire several times before I have to take it apart for

cleaning.

The heat of the

discharge was so intense that it blasted everything at the moment the

pulse took place. After the pulse was over molten aluminum bonded and

distributed itself along the rails. Finally copper oxide coated

everything, but came off without much effort. Looks like a simple brush

should be able to clean the entire gun without the need for disassembly. I

may have to mill that blasted pit though. Its color seems to indicate that

the two metals have been alloyed.

10/20/02: Just back

from the Wisconsin Dells Teslathon. Thanks for everyone who showed up!,

and a big thank you for D.C. Cox for hosting this fantastic event! It was

well worth the 14 hour drive! Showing the Rail Gun to the public was quite

an experience: My project generated a lot of interest and I found myself

explaining over and over again its principle of operation to countless

interested High Voltage enthusiasts. I also got to discuss the more

technical parts of the project with some of the highly knowledgeable

people there, which gave me several new and interesting ideas to try.

3 shots in total were attempted at the event, all of them from a distance

of about 6 feet into a projectile stop which consisted of 2 sheets of wood

and 3 sheets of 1" thick high density foam to prevent ricochet. The first

shot was at 150PSI air, no energy on the capacitor bank. The projectile

penetrated the first foam sheet and got stuck there.

The

second short was at 4kJ and produced some interesting sparks. It

penetrated all 3 sheets of foam. Since everything seemed to be going well

I attempted a last shot with 15kJ, which produced a spectacular shower of

sparks that moved towards the target as a whole unit, scorching the foam.

It was surprisingly quiet. The tumbling projectile hit the foam flat and

stopped at the wood, denting it slightly. The

second short was at 4kJ and produced some interesting sparks. It

penetrated all 3 sheets of foam. Since everything seemed to be going well

I attempted a last shot with 15kJ, which produced a spectacular shower of

sparks that moved towards the target as a whole unit, scorching the foam.

It was surprisingly quiet. The tumbling projectile hit the foam flat and

stopped at the wood, denting it slightly.

Even at very high powers the gun still fired at subsonic velocities.

Looking at the video and projectile it becomes obvious that the greatest

part of the energy delivered at the shots was spent transforming the

armature and rails into a plasma, but this only occurred at the tip of the

projectile: The muzzle velocity for a 150PSI shot from the injector is

somewhere around 100meters per second. At that velocity, a pulse length of

100uS will only apply power to the projectile during its first 1cm travel

on the rails: I.E. Before the projectile had even fully entered the gun

the pulse was already over; since the magnetic field never got behind the

back of the projectile, acceleration was negligible.

Even at very high powers the gun still fired at subsonic velocities.

Looking at the video and projectile it becomes obvious that the greatest

part of the energy delivered at the shots was spent transforming the

armature and rails into a plasma, but this only occurred at the tip of the

projectile: The muzzle velocity for a 150PSI shot from the injector is

somewhere around 100meters per second. At that velocity, a pulse length of

100uS will only apply power to the projectile during its first 1cm travel

on the rails: I.E. Before the projectile had even fully entered the gun

the pulse was already over; since the magnetic field never got behind the

back of the projectile, acceleration was negligible.

Before the gun can be made to work with a metal armature an inductor may

have to be built and added to the circuit so as to slow the pulse down to

the point where the projectile receives power during its entire travel.

Check back Monday for pictures of the rails!

|